When you’re up against tight budgets, maximizing the ROI on your existing foodservice equipment is a must. If you can squeeze more value out of your equipment, you can keep costs down, conserve precious cash, and avoid replacing equipment prematurely. Starting off with quality equipment is key, of course, but there’s more to it than that. With the right steps and a little TLC, you can get more value out of your equipment. Here’s how.

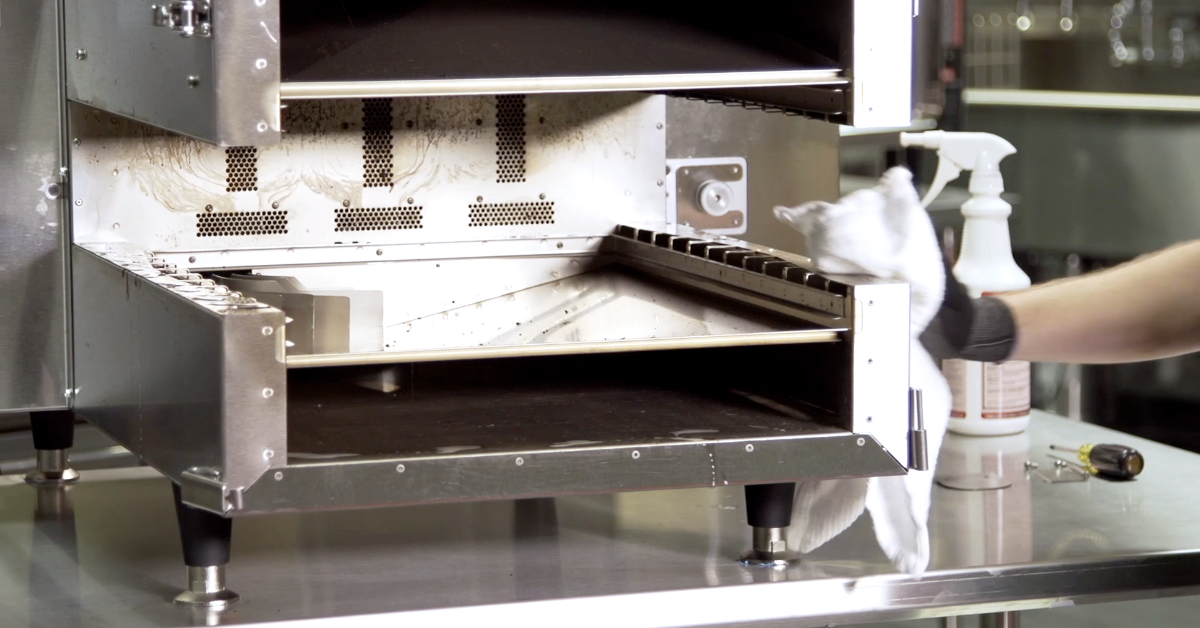

Keep it clean.

Regularly cleaning your equipment can have a significant impact on its longevity. Without it, food and grime can build up quickly, causing equipment parts to rust or even worse — malfunction. A regular cleaning routine is a critical component in preserving your equipment for the long haul. As you’re establishing your routine, let your equipment manual be your guide. Each piece of equipment has its own set of cleaning instructions, including which cleaning products to use, so play it safe and check the manual.

Stay on top of service.

Keep your equipment in good health by sticking to a regular cadence of service check-ups. Consult your service team to see how often they recommend equipment inspections, then pencil those dates in on the calendar. By doing this, you can ensure your equipment’s moving parts are in good shape. And if they’re not, you can catch small issues before they turn into bigger ones. If you wait too long, small issues can snowball, sticking you with an expensive service repair bill or even worse — a problem that can’t be fixed.

Keep replacement parts on hand.

Not every issue requires a service call, however. If it’s a minor part that needs to be replaced, you can fix it in-house if you have the right parts available. This saves you money in more ways than one. First, you can avoid additional service costs. And since you’re potentially eliminating downtime where you’d otherwise be making sales, you cut those losses. As with any equipment-related matters, check the manual to see which components need regular replacement. Keep those on-hand and while you’re at it, stock up on any other parts (e.g., filters, hardware or electrical components) you may need to keep equipment in mint condition.

Keep it out of harm’s way.

Believe it or not, where you position equipment within your foodservice facility can impact its lifespan. You want to position it so it’s conveniently located, of course, but make sure it’s not exposed to excess wear and tear. For example, keep electrical equipment and cords a safe distance from the sink, so they’re not at risk of getting wet. Or if there’s an area of the kitchen that’s more prone to collecting dust and debris, steer your equipment clear of it. And situate it so staff is less likely to bump into it.

Position it for efficiency.

The harder a piece of equipment has to work, the more it’s strained. Be thoughtful about where you’re placing your equipment so it’s set up for success. Distance heat-producing equipment from refrigeration equipment and drafty doors, so it doesn’t have to work harder than necessary to achieve a desired temperature. And leave ventilation room for equipment to expel hot air as part of its natural cooling process so it doesn’t overheat. Not only does this prevent premature malfunctioning, but as a bonus, it cuts back on energy costs.

Take advantage of multipurpose functionality.

In addition to these maintenance measures, make sure you’re getting the full value out of your equipment and its capabilities. If you have multi-purpose equipment with more than one intended use, don’t miss out on it. “The more, the merrier” doesn’t apply when it comes to equipment. Multipurpose equipment can save you money and space, so take advantage of it. With a piece of equipment like Ovention’s Shuttle® 2000 oven, for example, you have the capabilities of a traditional conveyor oven and closed cavity oven wrapped into one — which means you get more for your money.

Go easy on your budget.

With proper care and attention, you can make your equipment last longer and stretch your dollars further.

If you value precision and volume, Ovention has the perfect oven to fit your operation. The Shuttle sets the new standard for conveyor ovens everywhere. No other oven can operate as both a conveyor and a closed-cavity oven.

Cook a full menu of delicious offerings without an oven hood. The Ovention Matchbox 1718/1313 takes the traditional conveyor oven to a whole new level.

Simple, smart and the right fit for operators looking for a high-throughput conveyor oven. The Ovention Conveyor Oven is the most technologically elegant and operator-friendly conveyor on the market today.

Cook a full menu better, faster, and easier. The Ovention Matchbox M360 has Precision Impingement® technology, a unique cooking carousel, and a small footprint, making it the perfect fit for any operation.

Finish your plates with ease and precision with this robust IR finishing conveyor. Melt, sear, toast, and finish to perfection with this operator-friendly, quiet conveyor.

Revolutionary infusion of Linear Impingement and Infrared (IR) technologies. Independently controlled top and bottom cavities, each with its own interior light and control panel.

Introducing MiSA; Microwave Speed Assist. Higher quality, higher speed, smaller footprint.

Ventless ovens are often defined by what they don’t require: a hood, ductwork, or a major build-out. But that only […]

Speed of service is not just a front-of-house concern. It is one of the strongest revenue drivers in a foodservice […]

Used plates pass through your kitchen all day long, often without a second glance. But each one carries quiet feedback […]

Our goal is to partner with you to help you build your business. We will set up a demonstration that suits your needs, whether you want us to cook your current product, show you a range of new products, or do a side-by-side comparison with another oven we are ready to show you what Ovention can do.

Please complete ALL the fields below to schedule a demo.*

Scroll down to discover more

Experience an Ovention oven in action. We have test kitchens all across the country and representatives waiting to demonstrate our award-winning technology and ease of use. Contact us today to learn how one of our ovens can elevate your culinary versatility and build your business.

Cooked with Conveyor 2600/2000